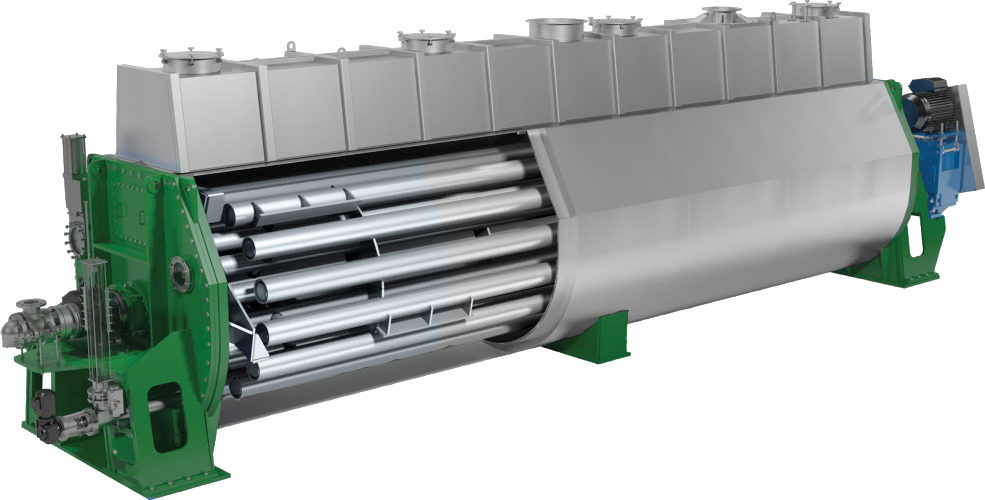

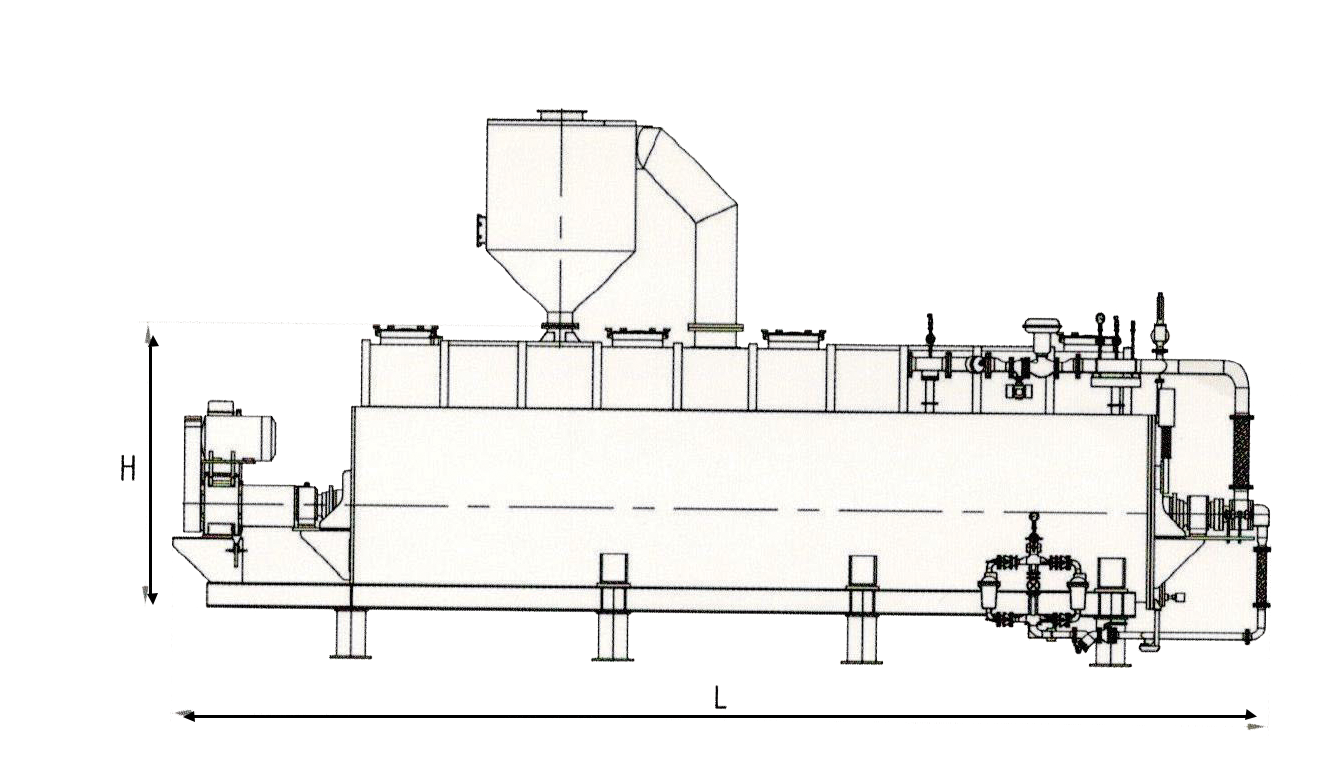

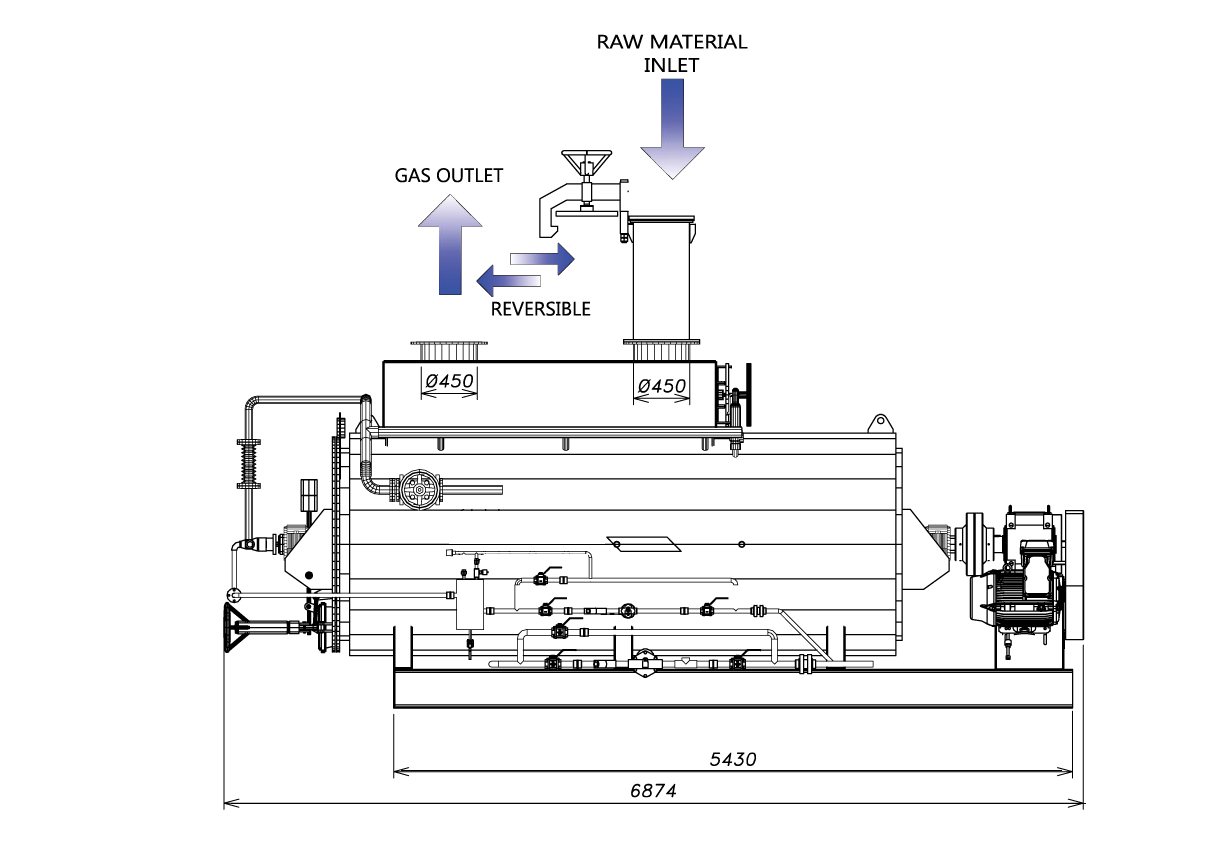

By-products such as meat, bone and fat is part of your processing setup, an indirect steam-heated Meatek Continuous Cooker can help you improve both operating efficiency and profit margins from such inputs.

Designed to use steam pressures of up to 10 bar, our designs provide capacities from 1,000 kg/hour up to 10,000 kg/hour and you can easily adjust cooking temperatures to match the specifics of your particular processing requirements and the raw material specifications you have available.

The raw material enter at the bottom of the cooker and discharge at the top, forcing the fat and bone through the cooker. Tallow is pumped in to keep the material flowing through the cooker, and is continually re-circulated for maximum thermal efficiency. A sophisticated automatic level control system regulates the input flows to prevent any cooking inefficiencies associated with under- or overfilling.

- Low upfront purchasing costs, helping keep capital expenditure down

- Low operating costs resulting from uncomplicated design, ease of operation and solidly engineered durability

- Greater cooking capacity per unit of heating area than any other type of cooker

- High evaporation rate

- Consistent cooking results, optimized by automatic temperature and level control

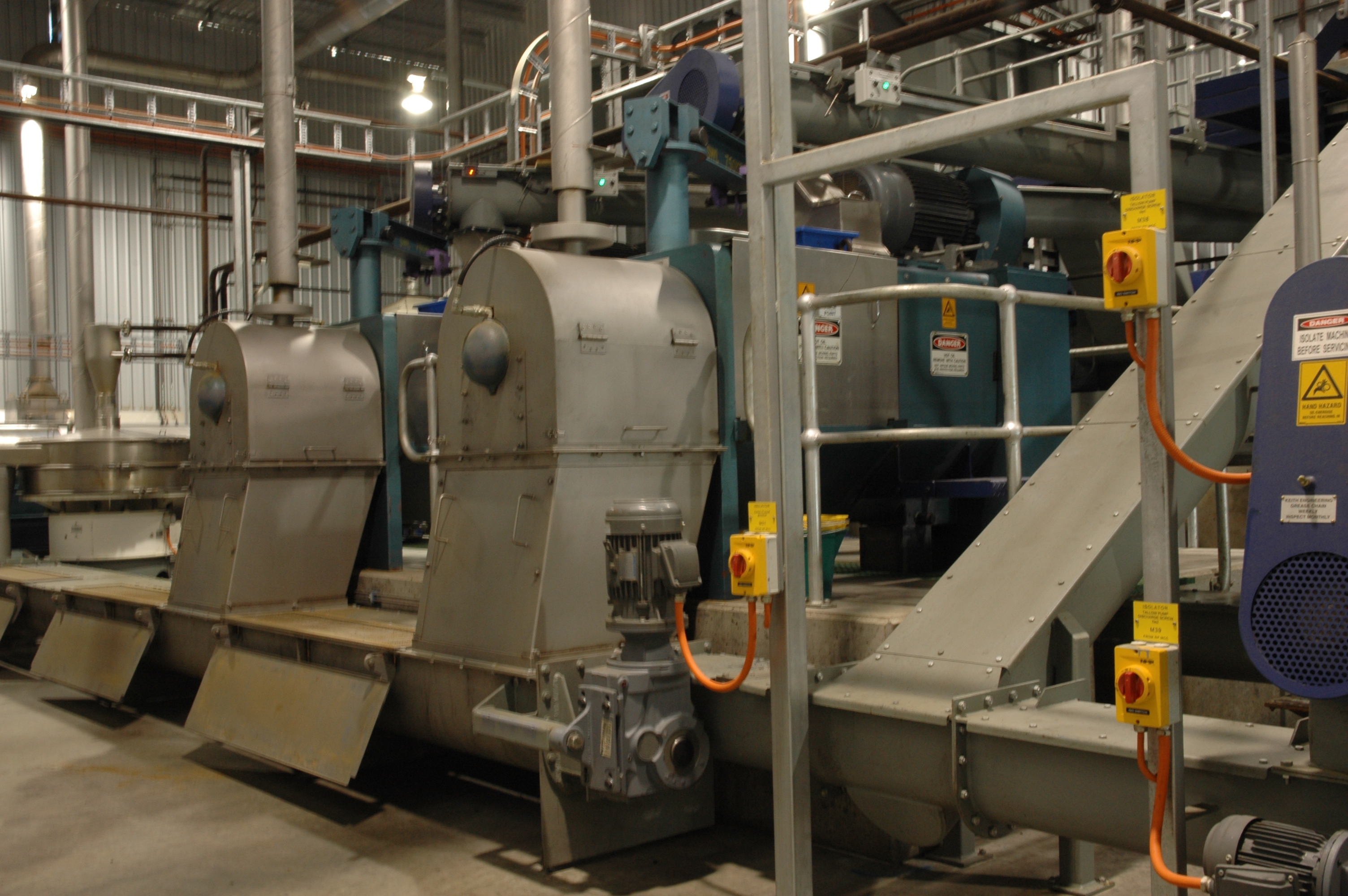

- Cooking finely crushed, relatively homogenous animal by-products as part of dry rendering processes

- Continuous cooking of meat, bone and fat in dry rendering processes for poultry or meat

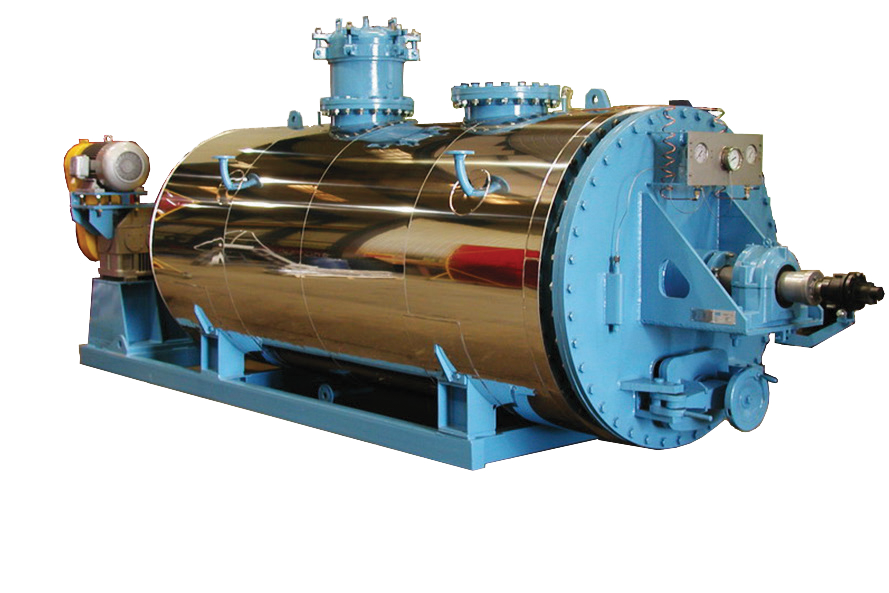

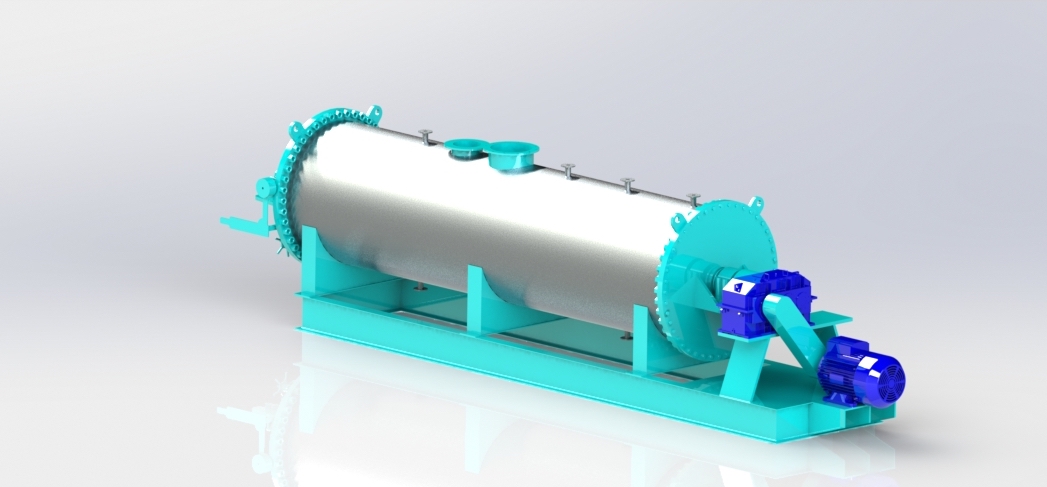

Making sure there is no water left in the input material is crucial prior to fat separation. This makes an effective cooker vital for any batch-based dry rendering process to operate profitably.

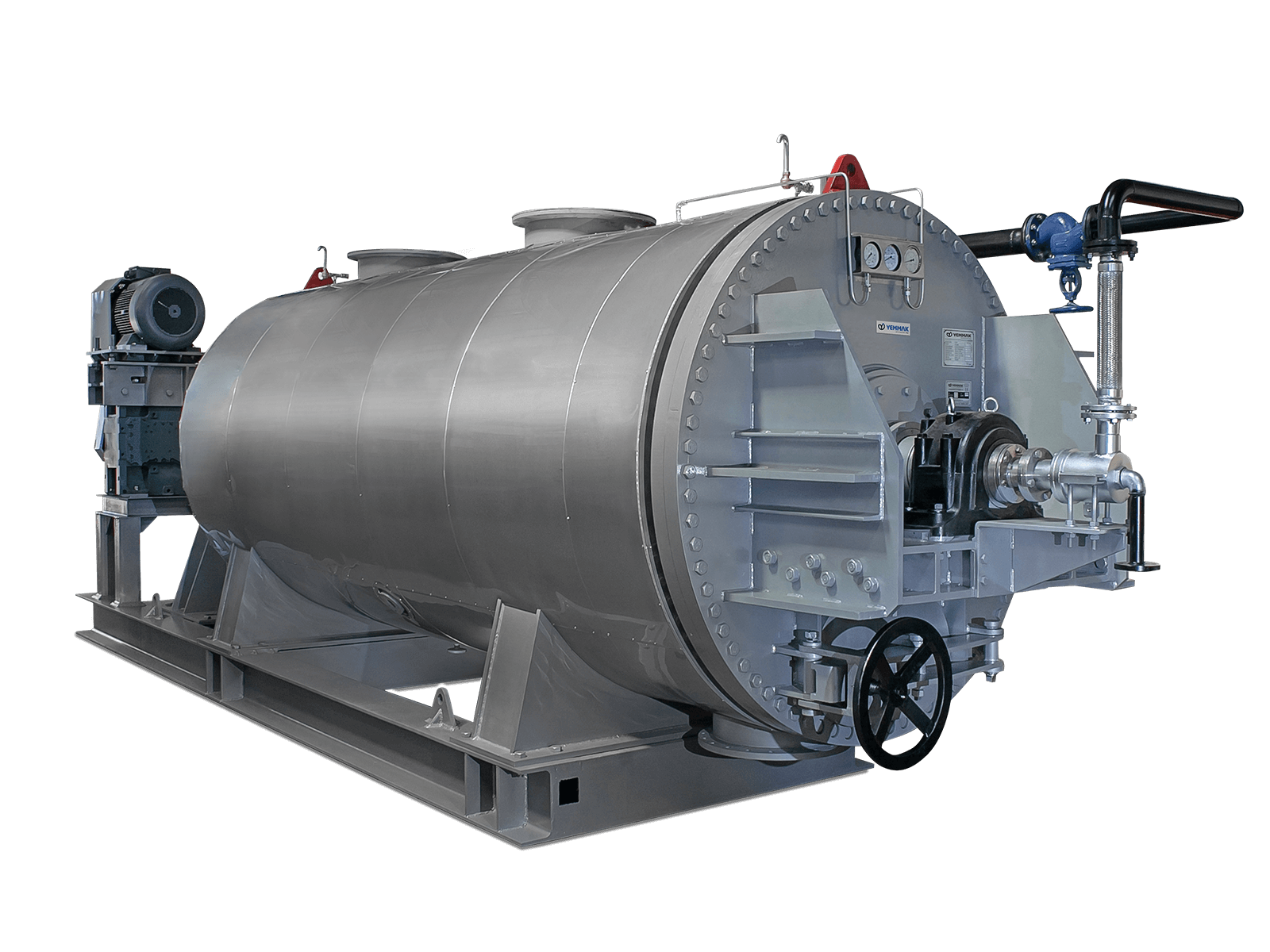

The Meatek Batch Cooker is quick-to-install unit that you can use for the cooking, pressure cooking, hydrolysis or drying of an exceptional range of animal and poultry by-products. These include mixed meat offal and bones, poultry offal and wet feathers.

It can operate at the 133°C temperatures important for sterilization, Furthermore, our well-proven cooker can operate under pressures of up to 10 bar, ensuring your processing setup complies with the 2009/2011 EU Animal By-products Directive and can even process inputs containing hair, wool or feathers, for use in pet food. Cooking under pressure means any required sterilization can take place at temperatures down to 70–80°C.

The batch cooker may be supplied with manual or automatic discharge outlet.

We also supply additional equipment such as:

- Our latest Single Batch cookers operate from 1 to 8 ton per hour, simple, rugged equipment for effective cooking and drying in batches – pressurized if required

- Very versatile – ideal for heating and drying a wide range of animal and poultry by-products

- Delivered pre-configured with all necessary valves, instruments, steam trap system, safety valve and insulation as standard

- Effective control of temperature, pressure and retention time ensures best-quality output

Applicable for:

-

- As part of high-temperature dry rendering lines in meat or poultry processing plants

- Poultry rendering operations involving hydrolysis of the feathers

- Pressure cooking animal by-products containing wool or hair into pet food

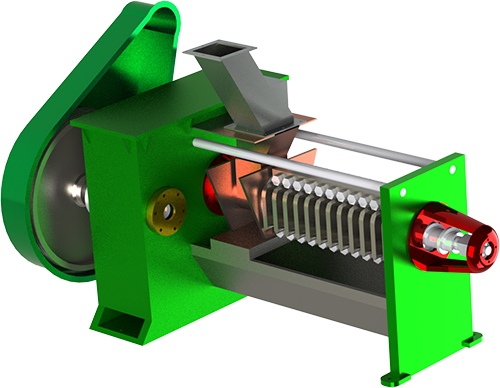

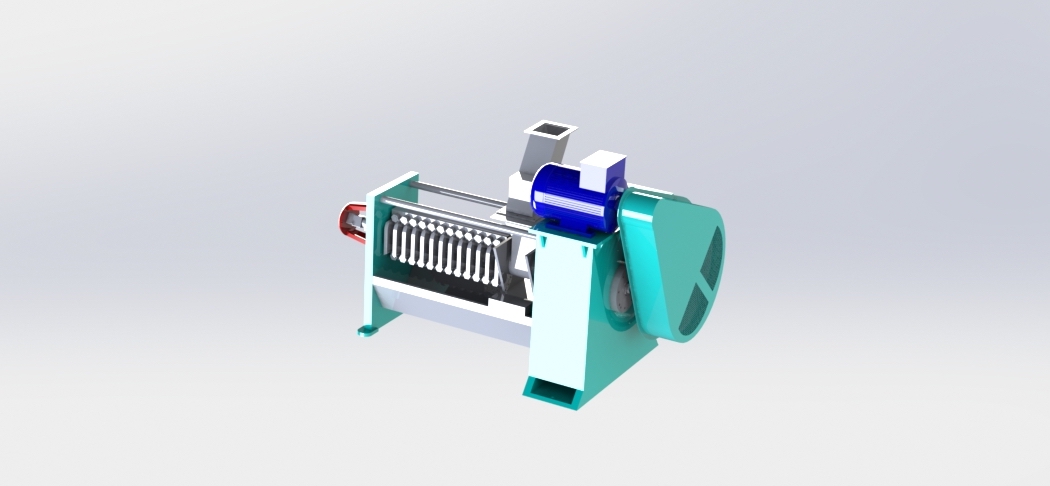

Screw Press provides highly effective mechanical extraction of the fat content from cooked and dried animal and poultry by-products, in a continuous flow. This enables you to achieve a hard cake with a low fat content.

As the greaves pass along the single conical screw, the fat is pressed out into the surrounding enclosure, and the greaves are discharged as press cake. The fat (along with any solids – often known as fines) runs into a collector trough, where a screw moves it to the outlet.

These solidly built units are simple but effective, ensuring maximum reliability and low service and maintenance costs. Two different models are currently available:

- STD model with hydraulically adjustable choke in the outlet

- Longer, high-capacity model with fewer moving parts and no choke in the outlet

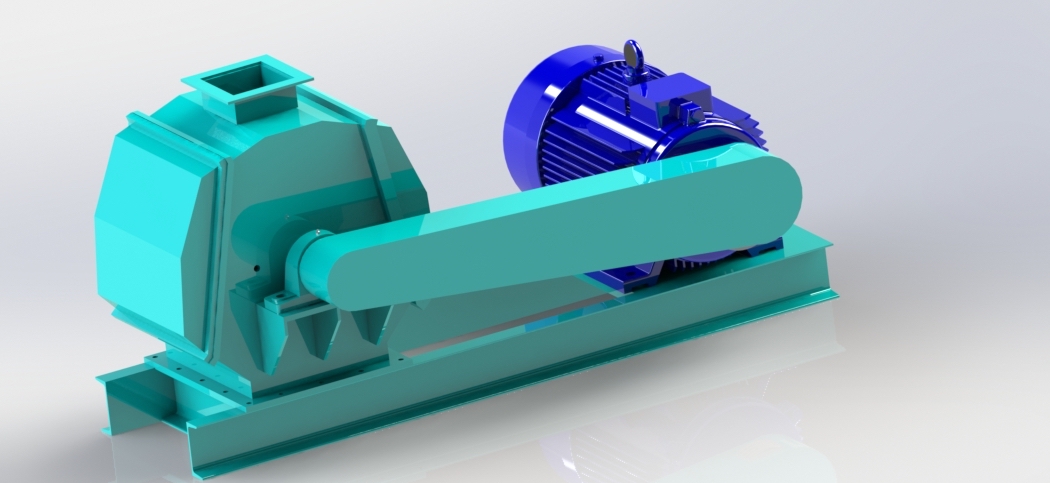

This is a complete system, featuring a conveyor under the platform on which the hammer mill is mounted, and an extractor fan that draws air through the system, keeping everything cool and evacuating dust to a self-cleaning filter bag.

It is a very efficient solution that uses a much smaller motor than most other comparable systems, running cooler and using less energy.

- Complete system for grinding meal that’s relatively brittle after drying

- Installed after a dryer in wet rendering processes

- Installed after a press in dry rendering processes

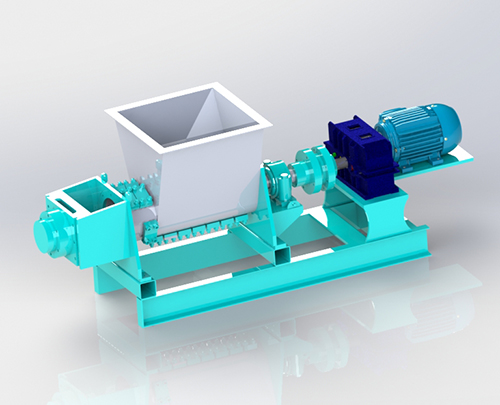

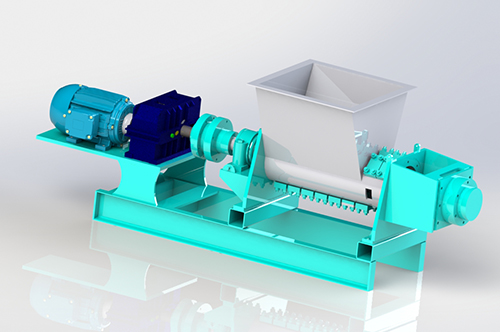

Pre-breaker is particularly rugged and hardwearing, designed for breaking down complete carcasses as well as all types of offal and bones from meat and poultry slaughterhouses, so they can be used more effectively in rendering processes.

Pre-breakers are used for the initial breaking down of input material to particles over 30 mm in size. They are ideal as a first stage prior to crushers, enabling you to align these initial steps with overall efficiency requirements for your process, based on particle size.

The low-speed breaker shaft makes sure the unit can deal with any foreign objects (such as metal) in the input material. You can select motor size and breaker shaft speed based on the amount of material you need to break down, and the output capacity you require. This helps keep operating costs down.

- First stage after material bins

- Installed upstream from crushers, fine crushers, etc.

- In any kind of rendering processes